We'll be learn about the following subjects:

- What exactly is the Air/Fuel Ratio (AFR)?

- What is Lambda, and how do AFR and Lambda relate to each other?

What is The Air/Fuel Ratio, and Why Does it Matter in Petrol Engines?

Internal ignition engines generate power by igniting fuel and oxygen from the air. Certain amounts of fuel and air must be delivered in the combustion chamber in order to ensure the combustion process. This means that the air-fuel ratio must be within a certain range to form the ignition in the internal combustion engine.

The air-fuel ratio is one of the most significant tuning and remap concepts. The mixing ratio or proportion of air and fuel supplied to the engine through the fuel system is known as the air-fuel ratio, or AFR. Stoichiometric air-fuel ratio is the optimal theoretical air-fuel ratio for full ignition. The stoichiometric air-fuel ratio for a petrol engine is roughly 14.7:1. This means that 1 gram of fuel requires 14.7 grams of air to totally burn. Additionally, even if the AFR is not stoichiometric, combustion still continues. Furthermore, When all of the fuel is burned, complete combustion occurs, and there will be no unburned fuel in the exhaust gas. However, combustion will never be complete due to changing conditions and a limited combustion time. As a result, this ratio will vary depending on the engine's operating conditions.

The air-fuel mixture is considered lean when the air-fuel ratio exceeds the stoichiometric ratio. The air-fuel mixture is described as rich when the air-fuel ratio is less than the stoichiometric ratio. For a petrol engine, an AFR of 16.5:1 is lean, whereas 13.0:1 is rich. You might be asking why the air-to-fuel ratio isn't a constant amount rather fluctuates. The variable air-to-fuel ratio refers to the fact that the engine operates under a variety of conditions, each of which requires a different AFR. Generally, lean and rich fuels have distinct qualities, and they are employed in different engine conditions based on those characteristics.

Engine performance, emissions, fuel economy, and lifetime are all affected differently by lean or rich fuel. Low fuel consumption, poor engine performance, high temperature, generation of nitrogen oxides, and rough idle are some of the characteristics of lean fuel. Rich fuel can cause excessive fuel consumption, improved engine performance, high carbon monoxide emissions, a pungent or rotten egg smell, carbon deposits on valves and pistons, and other issues. As a result, the engine's AFR must change frequently.

For example, we may require more fuel to have more power from a cold start to a warm-up moment or at full gear time; the air-fuel ratio will typically not be 14.7 and will be between 11 and 13 depending on the engine. AFR is normally between 10 and 11 at full load in forced induction engines to make the engine run cooler in those working conditions since richer fuel makes the engine cooler. For example, in cruise mode, the engine can use lean fuel of 15.5/1, resulting in lower fuel consumption.

The lowest AFR for the combustion process in a petrol engine is roughly 6:1, while the maximum may reach up to 20:1.

There are numerous AFR ratios, which are typically as follows.

- 6 AFR - Rich Burn Limit (engine fully warm)

- 9 AFR - Black Smoke Low Power

- 11.5 AFR - Best Rich Torque at Wide Open Throttle (WOT)

12.2 AFR - Safe Best Power at Wide Open Throttle (WOT)

- 12.8 AFR - Lean Best Power at Wide Open Throttle (WOT)

- 13.3 AFR - Lean Best Torque

- 14.7 AFR - Stoichiometric Air/Fuel Ratio Value

- 15.5 AFR - Lean Cruise

- 16.5 AFR - Usual Best Economy

- 18 AFR - Carbureted Lean Burn Limit

- 22 AFR - EFI Lean Burn Limit

As you can see, an engine must get the necessary AFR in other working areas in order to perform well in different conditions. Although, these numbers are indicative and do not apply to all engines or working conditions.

AFR in Different Engine Working Condition:

Idle:

The ratio in a closed loop at idle conditions is generally 14.7/1. Maintaining the engine close to this Air-Fuel Ratio reduces fuel consumption and emissions.

Wide open throttle or full load:

In forced induction engines, turbochargers, and superchargers, an AFR equivalent ratio of 11.8 to 11.5 can be used. The AFR ratio of 12.6 to 13.0 is ideal for maximum power in the natural respiration engine.

Acceleration:

With the extra fuel given by acceleration enrichment, the engine demands a richer mixture during acceleration than during steady-state operating. The air/fuel ratio will normally decrease 1 to 1.5 ratios from its static level under hard acceleration. The amount of acceleration enrichment that is required is normally found by trial and error, and this is best done on the road rather than on the dyno. Acceleration enrichment should be leaned out until a flat spot appears, then just enough fuel should be supplied to eliminate the flat spot. This method generally provides the most incisive results. Flat spots will emerge from both over-rich and over-lean acceleration enrichment, and a greater quantity of acceleration enrichment is required at lower engine rpm than at higher revolutions.

Over-run:

The ECU strategy generally regulates fuel economy by cutting off fuel injection during overrun or deceleration circumstances. The cut-off fuel or the AFR might both be extremely lean.

What Exactly is Lambda?

The Greek letter Lambda can also be used to express the Air Fuel Ratio. Lambda is obtained by dividing the actual AFR by the stoichiometric AFR.

Lambda = actual AFR / stoichiometric AFR

The lambda equals one when the real AFR equals the stoichiometric AFR. That is, the lambda of AFR 1 = 14.7 / 1

Lambda = (14.7/1) ÷ (14.7/1) = 1.0

If, for example, the air-fuel ratio is 13.1, we must divide 1314.7 to find the value of lambda. The lambda value is 0.88.

If the AFR is equal to 16, the lambda is 1.088, according to what we said. Therefore, we can conclude from these calculations and relationships that:

So, a lambda more than one, such as 1.2, represents a leaner air fuel ratio, whereas a lambda less than one, such as 0.88, represents a richer air fuel ratio.

In other words, when we say AFR 14.7/1, we're talking about 14.7 units of air and one unit of fuel (lambda 1).

Now, if this ratio is 13.1, it means that there is less air in the mixture, implying that the fuel is richer.

AFR in Diesel Engines:

The best Air-Fuel Ratio (AFR) for diesel engines depends on the engine's operating conditions and its design, but here's a general explanation:

Ideal AFR for Diesel Engines:

Unlike gasoline engines that typically operate at a stoichiometric AFR of around 14.7:1 (air to fuel by mass), diesel engines run on a leaner mixture. This means they use more air relative to the amount of fuel.

The stoichiometric AFR (Air-Fuel Ratio) for diesel engines is 14.55:1, but typical AFR ranges for diesel engines are:

At idle or low load: 40:1 to 100:1

At medium load: 25:1 to 40:1

At full load (maximum power): 16:1 to 20:1

With a simple calculation, we can conclude that the best lambda value for diesel engines under full load is approximately between 1.09 (AFR 16:1) and 1.37 (AFR 20:1).

1.09=14.55/16

18/14.55=1.237

So, the best AFR for diesel engines at full load is usually between 16:1 and 18:1. This range offers a good balance of power, fuel efficiency, and safe combustion temperatures.

Why Diesel Engines Run Leaner?

Diesel engines use compression ignition, not spark ignition. Air is compressed first, then fuel is injected directly into the hot, high-pressure air. Because there is no need for a precisely mixed air-fuel charge like in petrol engines, diesel engines can run with excess air most of the time. This results in:

- Better fuel economy

- Lower exhaust temperatures

- Improved combustion stability

- Lower CO and HC emissions

Rich vs. Lean in Diesel Tuning:

Running too rich (low AFR): Increases smoke (soot), raises exhaust temperatures, and can cause engine damage.

Running too lean (high AFR): Reduces power, increases NOx emissions, and may cause misfires or incomplete combustion at very low fuel rates.

What Impact Does The Air/Fuel Ratio Have on Engine Performance?

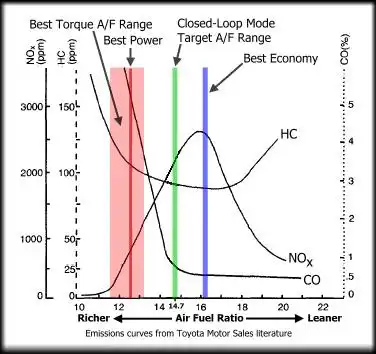

According to our explanations, the engine maximum power can be achieved at AFR 12.6 or lambda 0.86 in the Air/Fuel Ratio graph. If you look closely, you'll notice that the lambda is 0.86 less than one, which is in the rich area. You can see that the engine power has reduced on the right side of the diagram.

We want to teach you about the relationship between AFR and different pollutants. In this case, we can say that if AFR is in the rich range, i.e. The lambda value is smaller than 1, where the maximum engine power is obtained in this area, the amount of CO and HC has increased. However, NOX decreases. The low combustion chamber temperature and rich air-fuel ratio reduce NOX emissions. But when the AFR is adjusted to stoichiometric, HC and CO fall to their lowest levels, while NOX increases to its maximum. The higher temperature of the combustion chamber is the cause of the increase in NOX.

Now, CO and NOX are lowered, but HC is raised, at AFR 15.5 or 16. which are the best values to obtain the optimum fuel consumption.

🏁The best fuel consumption and lowest pollution mode, according to the description, are in stoichiometric ratio. Therefore, in closed-loop mode, ECU keeps the AFR value around 14.7/1.

Given the fundamental facts we provided about AFR, this ratio has a significant impact on engine power, pollution, fuel consumption, part life, and other factors. To correctly regulate AFR in other operating conditions, ECU manufacturers employ different tables and fuel correction factors.

For normal fuel injection, ECUs frequently employ a table. Then, they employ different tables for closed-loop and full load modes, as well as temperature control for components protection. The quantity of these tables, the control strategy, and the complexity are different for each engine. For example, ECUs sometimes control AFR using the two main fuel tables.

However, the fuel control strategy in some modern engines employs hundreds of tables. The requested lambda and lambda for component protection and EGT are the most essential tables in fuel or AFR control. We'll go through these three tables in the following.

📍For more information and probable problems feel free to contact us: support@caracaltech.com