What is Engine Torque?

The Engine Torque in general means the multiplication of force on displacement:

Torque = Force (combustion) × Displacement (piston movement)

In simple terms, the definition of torque is twisting force that speaks to the engine's rotational force and measures how much of that twisting force is available.

What is Torque Based Engine Management System?

Nowadays, Torque based engine management is used as a standard in engine management systems.

As you know, some of the engine power is always used to overcome the engine’s internal friction. An idle engine always has to use torque to overcome this internal friction to stay idle. Consider the torque required to keep the engine running at idle T1.

Now, if you turn on the air condition, you have added a load to the engine, so the engine needs to produce more torque for this extra load so that the engine does not turn off. Consider this torque required for air conditioner compression to be T2.

Now, the driver presses the accelerator pedal to request torque from the ECU. Consider this torque request from the driver as a T3. There are also some additional loads on the engine, such as hydraulic power steering pump alternator, etc., all of which we consider T4.

All the above-mentioned cases are calculated in the case of external and internal torque request percentages through different modules of ECU. Then, these torque requirements (T1, T2, T3, T4, …., Tn, Tn+1) are coordinated by the torque requirement coordination module, which decides target torque requirements.

Therefore, ECU calculates all of the requested torques. Then, the torque execution module computes the fuel quantity, injection time and spark advance for the engine to generate the target torque.

The Optimal Engine Torque, Mathematical Model of The Engine Torque:

In Torque based engine management ECUs, a mathematical model of torque is defined in the case of a table in ECU at the time of ECU calibration after measuring the engine torque on a dynamometer. The torque that is measured by the dynamometer is called brake torque.

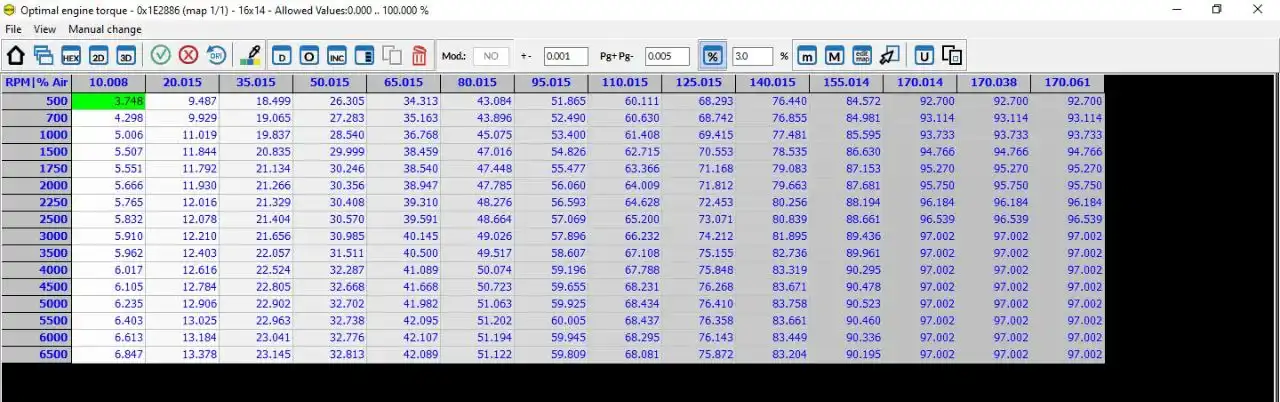

For instance, during a specific engine revolution and with a specified amount of intake air, the engine produces a certain torque. An engineer then adjusts the values and parameters to reach the optimum state of engine torque. The resulting numbers are recorded in a table labeled as “optimum engine torque”. This recorded data may be in the form of a large table with dimensions of 100×100 or even larger, but it is condensed into a more valuable and concise table with dimensions of 12×16 or 14×16. Here, you can see an example of an optimum engine torque table.

This table is a mathematical model engine torque in various engine revolutions and loads. The vertical axis is engine revolution and the horizontal axis is the cylinder air filling or engine load. The numbers in the table are the optimal engine torque in percentage of the Newton Meter. The optimum engine torque means the torque that the engine can produce and reach it in the optimal condition. The Torque based engine management system with this table precisely makes sense, i.e., on the basis of how much cylinders are filled with air at a given engine revolution, and how much torque the engine can produce.

📍For more information and probable problems feel free to contact us: support@caracaltech.com