- What is a data logger?

- How to use a data logger?

- How to analyze data from a data logger?

- What are the best data loggers?

🚩These are the questions we answer in this article.

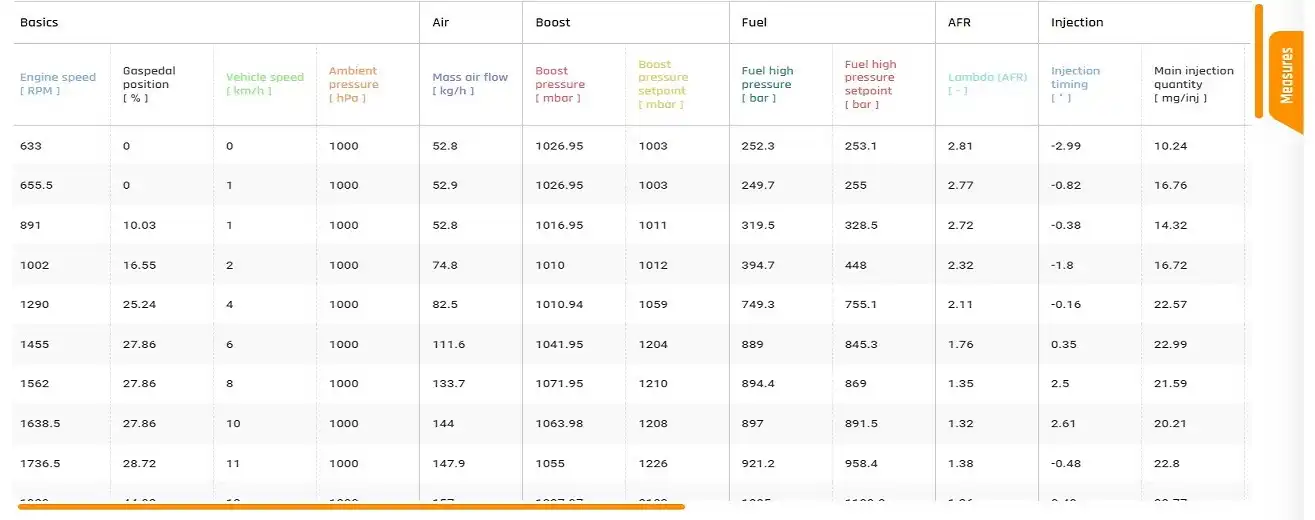

A data logger is a tool used for collecting information. This is the most general definition of a data logger. With a data logger, you can receive information such as pressure, intake air mass, boost, fuel, AFR, injection, and etc. from the vehicle's ECU.

❓But what is the purpose of this and why is it done? In fact, the question is what is the benefit of having this information?

✅There are various individuals and uses for data loggers. Engineers preparing a car for racing, tuners looking to enhance the performance and efficiency of their customers' vehicles, and even individuals seeking to measure specific parameters to address a particular issue, all fall into the category of those who use this device. Any other uses (which are many!) can probably be classified into these three main categories.

❓Another question that arises is what features a data logger should have and what type of data it should record?

✅Let's say that in general, there are different types of data loggers that record different parameters. In fact, it can be said that one of the differences between data loggers is the number of information they record (we are not concerned about the method and quality for now!). So, up to this point, the number of information that we receive from the data logger is an important point. With this explanation, you will come to the conclusion that most data loggers that record more information will also have a higher price.

Some ECU programmers, such as Autotuner and Flex, and many car diagnosis machines are also equipped with a data logger and are capable of recording ECU information. From the points that have been mentioned, we can conclude that the cost you are willing to pay for a data logger should align with the goal you have and the parameters you need, as the variety of products in this market is high and you will need to be able to update and adapt your tools to your needs and requirements.

Setting up a data logger:

Perhaps more important than knowing how to connect to a data logger and use it, is preparing the vehicle for using the data logger. But why is this important? The point is that the purpose of using a data logger is to obtain information. We all know that to analyze information as best as possible, we need certain skills, but if this information is incorrect or inaccurate, all subsequent analyses will be futile. Therefore, if we want to have more accurate data, we need to minimize error factors and bring the vehicle to the closest state to the test condition of the manufacturer. This means (for example) you need to adjust the tire pressure because too low or too high pressure can take friction out of its useful range. Or as another example, you need to adjust the coolant level, check the engine oil, ensure the cleanliness of the car's filters, and even make sure there is no extra load as it increases the car's mass, which clearly reduces efficiency.

After checking the initial items, it's time to establish a connection between the device and the ECU, which is done through the OBD port in most vehicles and data logger brands. Through this port, you can communicate with the ECU and extract information, read the ECU file, or even write new ECU tuning files.

Next, to establish a connection between the data logger and a device such as a laptop or your mobile phone, you need to install the data logger software (on the device being used). Also, it is important to check before purchasing a data logger what operating system the software supports and which operating systems it is compatible with.

After these steps, you can start working with the data logger. Do not panic and do not rush! The user interface of most data loggers is not designed in a way that will confuse you! So calmly extract the information and move on to the next step.

Data logger parameters:

After recording the initial data, the next important step is to analyze this data correctly. You will be faced with a large amount of data that you need to search for the information you need within them. However, the key point is right here: do not let the large volume of data confuse you. You need specific information that you are looking for. So ignore the information you do not need so that you can focus on the data you need. This may be your only way to start working with data loggers, but it also has another advantage. When you use simpler, clearer, and necessary information, your progress in working with data loggers will be faster, and you will become proficient in this work in a shorter period of time.

So do not forget this point and analyze the necessary and more familiar information with calmness and focus.

🏁The last step:

It's simple! You have done the analyses and come to the conclusion that the fan temperature needs to change, the AFR is not suitable, fuel consumption is high, or any other issue. So get to work; if you need to replace parts, do it, if you need to reprogram, reprogram, and if there are mechanical problems, fix them.

If you need data analysis for your work, if you want to analyze more advanced data, or if you are interested in learning this work in general, you can check out our data logger analysis course.

Best data loggers:

As mentioned, there are several brands of data loggers in the market, and indeed, good brands are not few. However, in this section, we have listed some of them for you, and we will gradually make this list more complete.

- CSS Electronics, CANedge2 & CANedge1

- vgate, vLinker MC+

- AUTEL, MaxiSys

- Magic Motorsport, Flex

- Motec, MoTeC

- AutoTuner

ECU Tuning Using Data Logging:

While ECU tuning can be done based on pre made files or general strategies, advanced and safe tuning requires real-time monitoring of engine behavior and this is where data logging comes into play.

As we explained, a data logger is a powerful diagnostic tool that records real-time performance data from various sensors while the engine is running, either on a dyno or during road testing. This information is critical in understanding how the engine is responding to different loads, throttle positions, boost pressures, and AFR. By analyzing this data, a tuner can make precise adjustments to optimize engine performance without risking damage.

Key Parameters to Monitor:

- Turbo Boost Pressure (MAP Sensor Data) Turbo pressure or boost level is a crucial indicator of how much air is being forced into the engine by the turbocharger. Excessively high boost can lead to knock or engine failure, while too little boost may cause underperformance. During tuning, boost levels are closely monitored to ensure they match desired targets and that the turbo is operating efficiently and safely. Adjusting the boost control maps (such as duty cycle or requested boost) must be done in line with turbo efficiency and safe limits.

- Air-Fuel Ratio (AFR) AFR is one of the most important parameters in tuning. It tells you the ratio of air to fuel in the combustion mixture. A lean mixture (too much air) can cause overheating and knock, while a rich mixture (too much fuel) can waste fuel and foul components like the DPF. Using a wideband O2 sensor, the data logger captures real AFR values under different conditions. Tuning the fuel injection maps and timing based on AFR data allows for more power and efficiency while maintaining engine safety.

- Exhaust Gas Temperature (EGT) High EGT can indicate overly aggressive fueling or turbo stress. Monitoring EGT during logging helps prevent thermal damage, especially in diesel engines or high-performance builds. Tuning should aim to keep EGTs within manufacturer-recommended limits.

- Injection Timing and Duration The timing of fuel injection directly affects combustion efficiency. A data logger can record when injection starts and ends relative to crankshaft position. If combustion starts too early or too late, power and efficiency drop. Fine-tuning timing based on logged values helps achieve smoother power delivery and better fuel economy.

- Throttle Position and Engine Load Throttle position and load input help correlate driving behavior to engine demand. These values help verify if fuel, boost, and timing maps are matching the driver’s request. For example, under high load, you want to see consistent boost and safe AFRs.

- Knock Retard or Detonation Some ECUs provide knock sensor data. If knock is detected, the ECU will pull timing to protect the engine. If knock retard is consistently logged, the ignition maps may be too aggressive and should be adjusted accordingly.

Usually, recording this data in 3rd or 4th gear is most effective. In other cases, if logging is needed in different gears, your tuner will let you know.

Once data is logged from a driving session or dyno run, the tuner imports the log into analysis software. By comparing logged data to map values in the ECU, they can identify inconsistencies or opportunities for improvement. For example, if boost builds too slowly, adjustments to the wastegate duty cycle, engine load, turbo response tables or etc. may help. If AFRs are too lean under load, more fuel may be added via the main injection map.

Data logging allows for iterative tuning; make changes, test the car, log data, and refine. It’s a cycle that, when done carefully, results in optimized performance, safer engine operation, and better drivability.

For example, in the picture below, which shows the data log of a McLaren 570S, we observe a drop in turbo pressure starting around 5800 RPM. These values are easily measurable from the data log, and with your ECU tuning knowledge, you can apply the necessary changes to the maps and limiters.

ECU tuning using a data logger is also covered in our courses, which you can view through this link.

📍If you have any question, feel free to contact us at: support@caracaltech.com